The door you choose for your workshop or machinery hall will affect both production and profitability. Your operations depend on smooth logistics. Every interruption costs time and money.

A workshop door that breaks down or needs constant repairs will slow traffic in and out of your facility. And breakdowns are not only expensive, they’re frustrating for both staff and customers.

That’s why the most important quality of a workshop door is simple: it must not fail.

Why an Industrial Folding Door is the Optimal Choice

For most workshops and machinery halls, an industrial folding door is the optimal solution. It’s durable, reliable, and because it opens sideways, drivers can clearly see whether there’s enough clearance to pass. That means fewer collisions compared to overhead sectional doors.

Why Reliability Is What Matters Most

If a door stops working, the operation stops.

If the operation stops, it costs time and money.

That’s why your door must work – every day, year after year.

Reliability isn’t about a single component. It’s about the whole system. Every part of a Torverk folding door is designed to last, to run smoothly, and to withstand tough conditions. That’s how you avoid costly downtime.

Examples of how Torverk builds for long-term reliability:

- Rigid, sandwich-constructed panels with hardened steel fittings resist deformation.

- Lift-off hinges with minimal friction – seals don’t drag or wear out.

- Motors and drive systems dimensioned for millions of cycles – and if something breaks, the motor can be disengaged so operations continue.

- Photo cells that aren’t affected by strong sunlight or shocks.

- Seals and gaskets that stay flexible even in severe cold.

- Safety edges with conductive rubber that maintain sensitivity year after year.

Whether you go with Torverk or any premium supplier, here´s what to focus on when choosing:

Key Considerations When Selecting a Folding Door for Workshops and Machinery Halls:

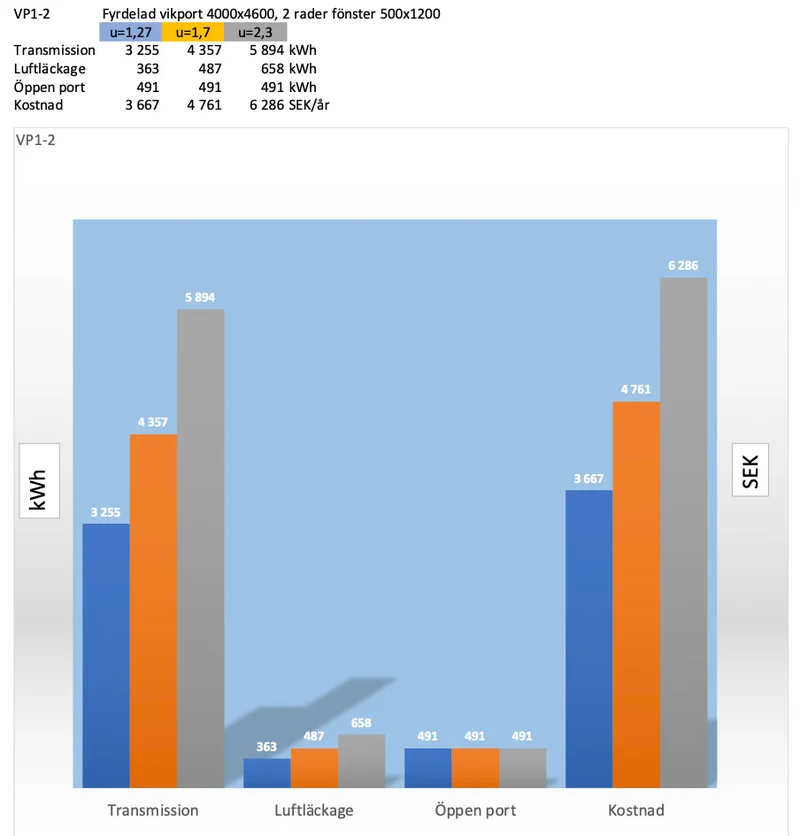

Calculation example from an industry site in Luleå. The blue bar represents a Torverk Q-door (with a U-value of 1.27). The analysis shows the annual savings compared to another door with lower insulation performance.

1. Insulation & Energy Efficiency

- If your facility is heated, choose a well-insulated door with a low U-value.

- Fast opening and closing minimizes heat loss during winter cycles.

- When closed, the door should act as a wall: keeping heat in, keeping cold and intruders out.

Here the pedestrian door is placed beside the main door. This reduces the number of frames in the door leaf and helps save energy.

2. Windows & Pedestrian Door Configuration (heat loss & usability)

- Keep glazing at a minimum: use as few and as small windows as possible. Every frame/joint is a thermal bridge and a potential air‑leak path, which increases both U‑value impact and T‑value (airtightness) losses.

- Place the wicket door beside the main door whenever possible. This reduces the number of window/door frames in the door leaf and lowers heat loss.

- If a separate pedestrian door isn''''''''''''''''t possible, a built‑in door is still far better than cycling the entire door for person traffic.

- If windows are required, choose insulated, low‑E, double‑glazed vision panels (warm‑edge spacers if available) and position at driver eye height to maintain sightlines without oversizing.

- Avoid many small panes that multiply frame perimeter; prefer fewer, compact vision panels with continuous, well‑sealed frames.

- For heated workshops, avoid large/full‑width glazing; keep vision panels functional rather than decorative.

5. Proper Sizing

- Door height should be 15–25 cm higher than the tallest vehicle.

- Width should exceed the widest vehicle by 120 cm.

- Oversizing costs energy and slows down operations.

Don´t make the door bigger than it has to be.

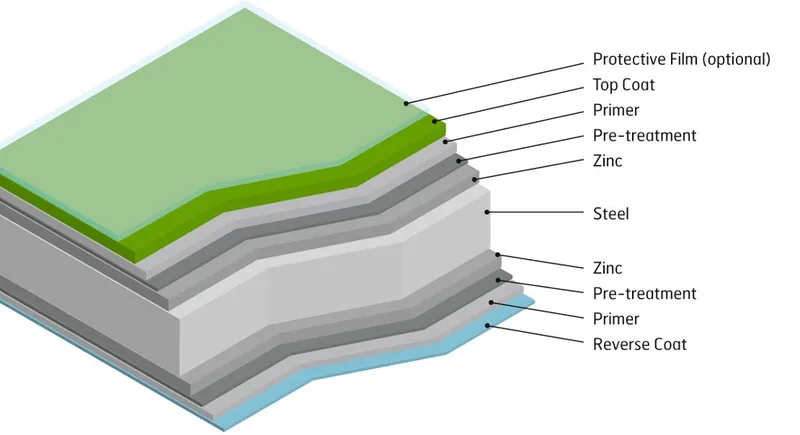

Torverk's panel steel has C5 corrosion protection, suited for harsh atmospheres.

7. Need Extra Rust Protection?

- Rust protection (C5 rating) is crucial for coastal or humidity-prone environments. Torverk´s panel steel has C5 corrosion protection, suited for harsh atmospheres.

- Torverk´s door cladding steel is protected with a five-layer paint an coating system.

Keep Logistics Running with a Trouble-Free Door

And last but not least, choose a folding industrial door that doesn''''''''t interfere with your logisticst and that has long-lasting performance with minimal maintenance.

Since 1962, Torverk has developed its doors in close cooperation with demanding customers such as fire services and heavy industry – environments where downtime is simply not an option. In practice, our doors often run problem-free for more than 30 years. Our doors are highly insulated and airtight, saving energy and creating a stable indoor climate.

One client even dubbed it “the best cost per kilo” – Torverk doesn’t skimp on materials. These doors are made to last.

We´re here to help!

Need help specifying the right door for your workshop or machinery hall? Our experts can guide you through the ideal combination of insulation, security, and operational efficiency for your application.